Stainless Steel Finish Chart

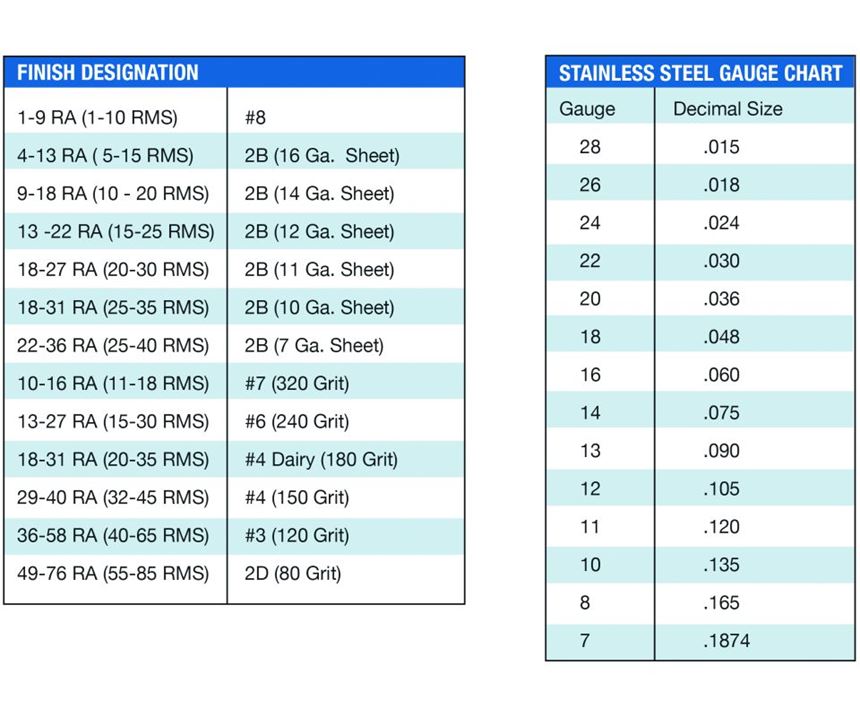

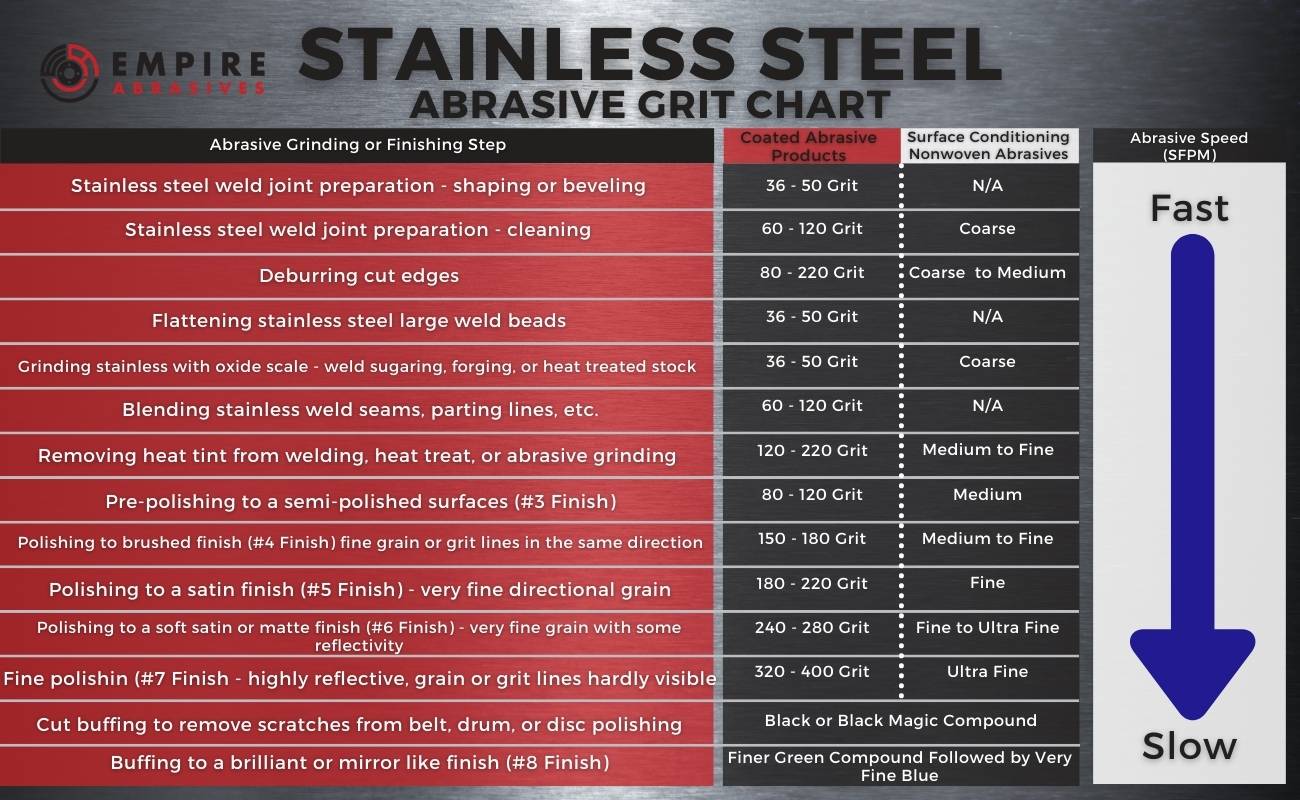

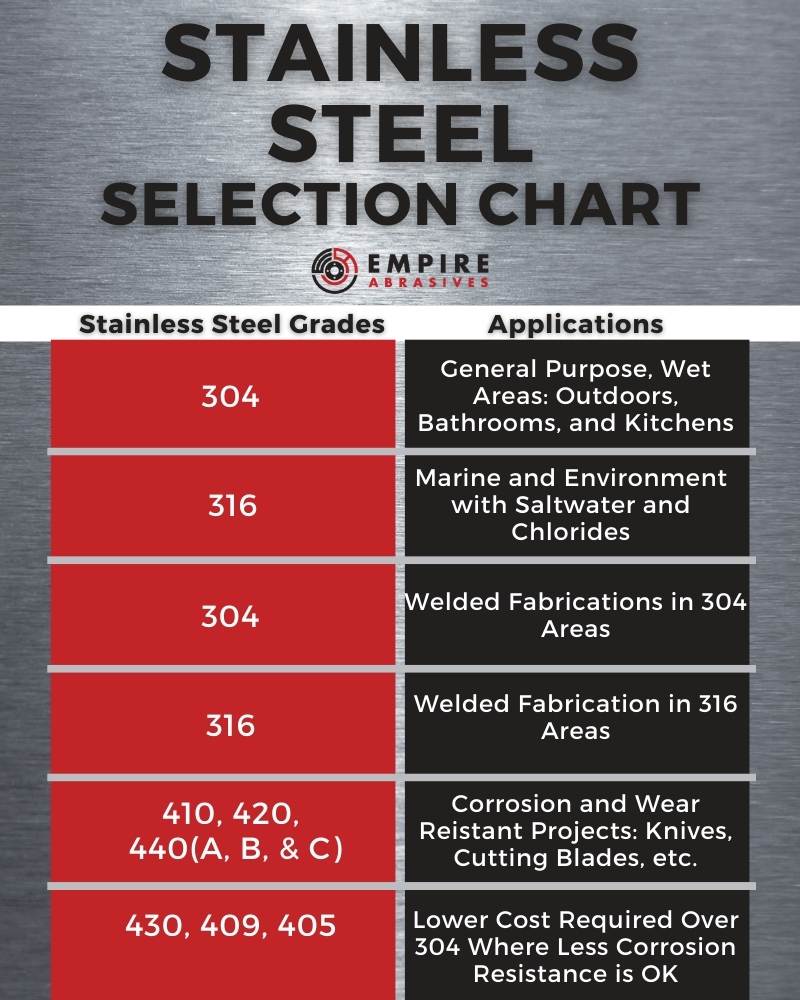

Stainless Steel Finish Chart - We are a global metalworking including metal finish and metal products. We’ll get into the details of each finish later in the article. Whether you need durability, corrosion resistance, a reflective surface, smoothness, or a specific grain pattern, any are available and desirable depending on the ultimate end use. 1 what is a stainless steel surface finish? Armed with the knowledge from this guide, you can make informed. Web stainless steel finishes according to en and astm equivalents. Web the surface finish of stainless steel affects much more than just its aesthetic — performance, reliability, and other factors can be greatly impacted. Values are usually given in microinches or micrometers. 2 what are the different types of stainless steel surface finishes? Which stainless steel mill finishes are popular? Web for example, the most commonly used finish for most stainless steel appliances is the no. Values are usually given in microinches or micrometers. Web stainless steel is not only versatile with various different grades and compositions, but also in its surface finishes. Surface finish formulas (turning) theory. Read this simplified explanation by raykam alloys and get your questions answered. Cutting commercial keys, i/c core keys, control keys, and master keys. Find the perfect finish for your project with our handy guide. You can think about finishing as a fabrication process applied to enhance the metal’s surface character. Below is an overview of the types of surface finishes available on. The surface roughness of the turning operation depends on the feedrate and the insert corner radius. Web discover our stainless steel finishes chart for an easy comparison of various finishes! 2 guidelines for comparing stainless steel finishes. Web stainless steel finishes according to en and astm equivalents. Web for example, the most commonly used finish for most stainless steel appliances is the no. Web ra (average roughness) is the most common in north america.it is the. Web for example, the most commonly used finish for most stainless steel appliances is the no. 7 finishes can be found in architectural components, such as ornamental trim and wall panels. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Web understand the stainless steel finishes as per astm and din standards.. You can think about finishing as a fabrication process applied to enhance the metal’s surface character. We are a global metalworking including metal finish and metal products. 1 finishes in stainless steel, the material must undergo hot rolling until it reaches the desired thickness. Calculate the feedrate that yields the required surface finish. The surface roughness of the turning operation. Cutting commercial keys, i/c core keys, control keys, and master keys. Web discover our stainless steel finishes chart for an easy comparison of various finishes! Below is an overview of the types of surface finishes available on. You can think about finishing as a fabrication process applied to enhance the metal’s surface character. 2 guidelines for comparing stainless steel finishes. Web discover our stainless steel finishes chart for an easy comparison of various finishes! Read this simplified explanation by raykam alloys and get your questions answered. Calculate the feedrate that yields the required surface finish. Find the perfect finish for your project with our handy guide. 1 what is a stainless steel surface finish? 3 basic stainless steel sheet finish designation. Can you recommend any brushed and polished finishes for stainless steel? This gives you a great overview of the possibilities using both standards. A lower feedrate, as does a larger corner radius, improves the surface finish. Examples include architectural structures, chemical equipment, and food and beverage manufacturing. What is the surface roughness of stainless steel? 1 what is a stainless steel surface finish? Values are usually given in microinches or micrometers. 2 what are the different types of stainless steel surface finishes? The surface roughness of the turning operation depends on the feedrate and the insert corner radius. 1 finishes in stainless steel, the material must undergo hot rolling until it reaches the desired thickness. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. 2.3 finish bright annealed (ba) 2.4 finish mechanically. Let’s start by comparing the en and astm finishes in a table format. Find the perfect finish for. Find the perfect finish for your project with our handy guide. 2.3 finish bright annealed (ba) 2.4 finish mechanically. Hzw’s surface finish designations are based on astm a240 standard. Web explore elkay's stainless steel finish chart for a comprehensive guide to our stunning finishes. The surface roughness of the turning operation depends on the feedrate and the insert corner radius. 2 what are the different types of stainless steel surface finishes? Web explore elkay's stainless steel finish chart for a comprehensive guide to our stunning finishes. Below is an overview of the types of surface finishes available on. Find the perfect look for your kitchen or workspace. What is a 2b polished finish on stainless steel? Below is an overview of the types of surface finishes available on. Web from the raw mill finish to the highly reflective no. Stainless steel finishes offer a range of benefits. 8 finish and specialized etched designs, each stainless steel finish has its unique characteristics and applications. Web stainless steel finishes according to en and astm equivalents. These finishes generally appear dark and varied, and they display the roughest and least uniform surface texture among all. Read this simplified explanation by raykam alloys and get your questions answered. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. What is the surface roughness of stainless steel? You may be aware of “mirror finish” and “mill finish”, but how exactly are these finishes achieved? This finish provides a nice bright, brushed appearance that will withstand daily use and mask the fingerprints, scuffs, scratches, etc. Whether you need durability, corrosion resistance, a reflective surface, smoothness, or a specific grain pattern, any are available and desirable depending on the ultimate end use. 2.3 finish bright annealed (ba) 2.4 finish mechanically. 2 guidelines for comparing stainless steel finishes. Let’s start by comparing the en and astm finishes in a table format. Web complete stainless steel surface finish chart 2024.Stainless Steel Surface Finish Chart vrogue.co

Stainless Steel Sheet and Plate Finishes Euro Steel, SA

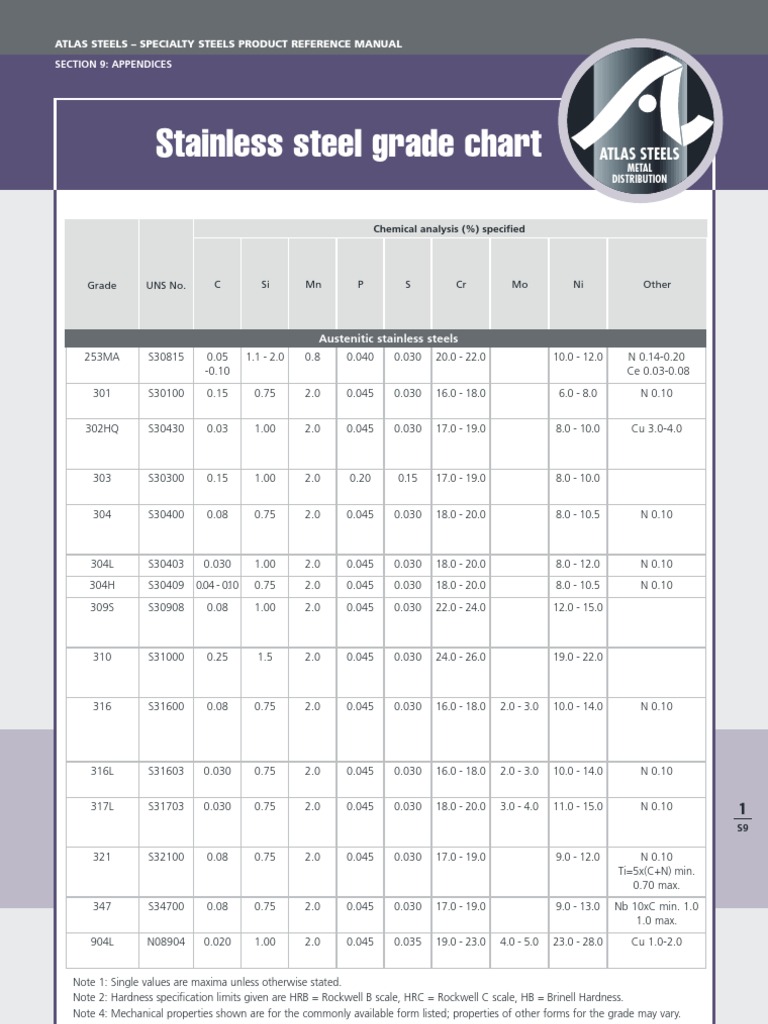

Stainless Steel Grade Chart PDF Stainless Steel Steel

Stainless Steel Finish Samples|KIKUKAWA

Stainless Steel Finish Chart

Steel Finish Chart Ponasa

Grit Surface Finish Chart

Stainless Steel Surface Finish Chart

Ultimate Guide Stainless Steel Fabrication, Grinding, and Finishing

Gallery Of Surface Roughness Conversion Chart Of Stai vrogue.co

This Gives You A Great Overview Of The Possibilities Using Both Standards.

1 Finishes In Stainless Steel, The Material Must Undergo Hot Rolling Until It Reaches The Desired Thickness.

Rz Is The Average Of The Highest Peak To The Lowest Valley Over 5 Sample Lengths.

Web Explore Elkay's Stainless Steel Finish Chart For A Comprehensive Guide To Our Stunning Finishes.

Related Post: