Mig Welding Chart

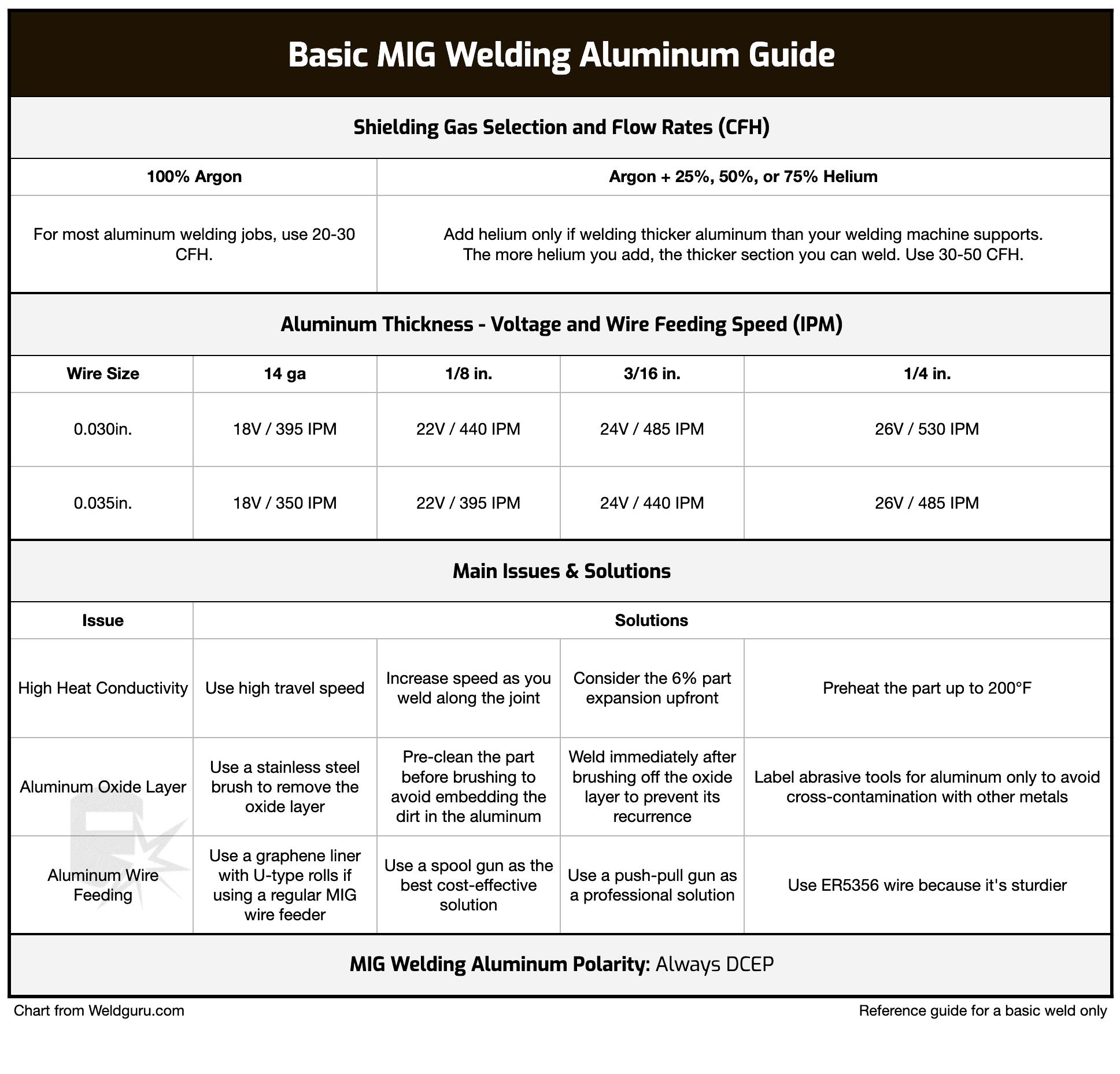

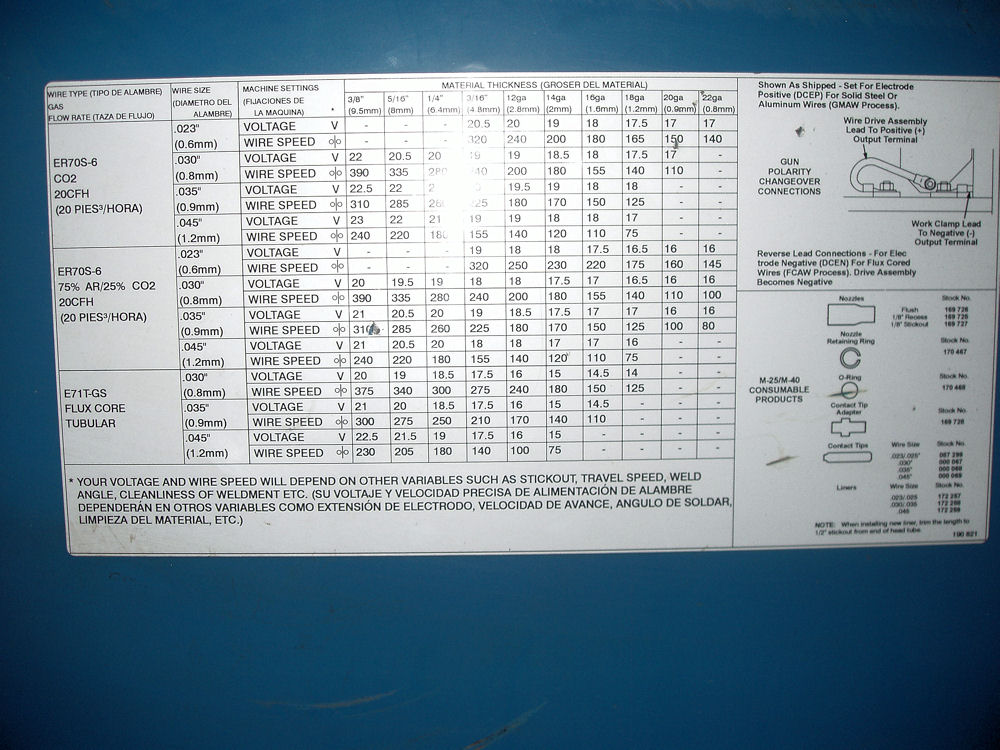

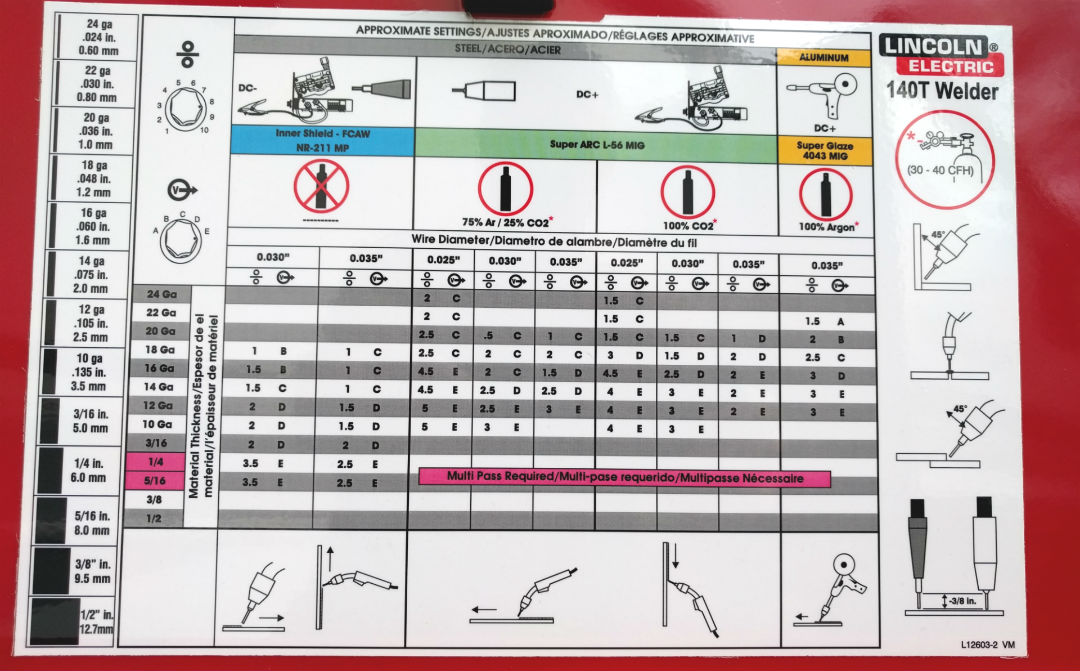

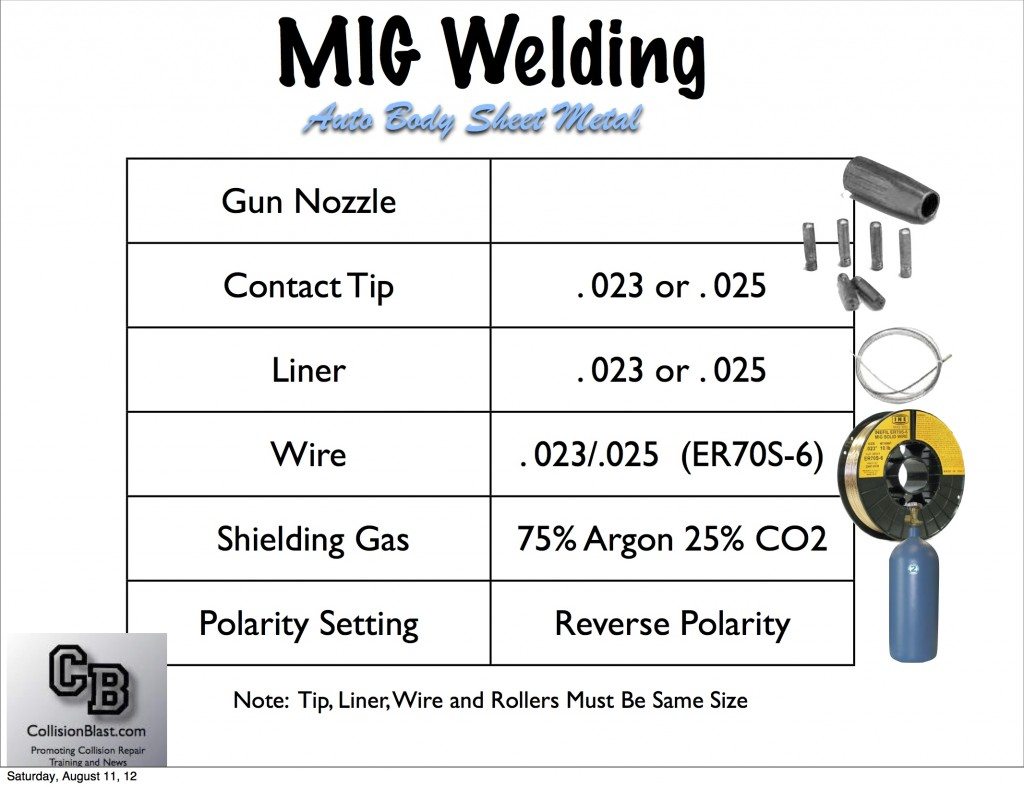

Mig Welding Chart - Web mig welder settings: One other thing to note here is that these settings are also affected by your welding technique, such as the pattern and speed you move your hand. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Web understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. There are many mig setting charts available from manufacturers that all vary. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. Nearly every mig welder has a chart — including my millermatic® 211 — often just inside the hinged access cover, which gives you the suggested settings. How to adjust the gas flow rate? Before tackling any mig welding application, look at the charts and tips below. These are based on the material type and thickness, and. One other thing to note here is that these settings are also affected by your welding technique, such as the pattern and speed you move your hand. Web miller mig welding settings charts. Covering classifications, refrence charts and gas choices. Use these tips to get the best mig welds. How to adjust the gas flow rate? To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Web what material are you welding? Also, consider the amperage settings and the task at hand. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web the welding chart that comes with your machine undoubtedly provides the best guidelines for the welding start. These three settings must be perfectly aligned to get a perfect weld. Web metal inert gas (mig) welding is an arc welding process in which a solid wire (the filler metal) is continuously fed through the welding machine and into the weld pool that’s created by the arc to form a weld. Stainless steel and aluminium amps chart. Web mig. There are many mig setting charts available from manufacturers that all vary. Here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Before tackling any mig welding application, look at the charts and tips below. Web using the correct mig welding settings can make or break the quality of your finished product. To. Before tackling any mig welding application, look at the charts and tips below. Web in this article, we are going to take a look at how to set up a mig welder along with various other information like how to set up wire welder with gas, metal inert gas welding procedure, what is gmaw welding used for, etc. Web the. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. There might be variations with the settings depending on the manufacturer. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the. Stainless steel and aluminium amps chart. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web what material are you welding? Mig welding, also called metal inert gas, is widely used and practiced in various industrial zones to weld different metals, and multiple shielding gasses are. Stainless steel and aluminium amps chart. Web the welding chart that comes with your machine undoubtedly provides the best guidelines for the welding start. Covering classifications, refrence charts and gas choices. These are based on the material type and thickness, and. Web in this article, we are going to take a look at how to set up a mig welder. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web what material are you welding? Stainless steel and aluminium amps chart. But before using these values, we suggest that you have a decent understanding of your preferred metal. To ensure optimal results, select the appropriate gauge. Use these tips to get the best mig welds. Before tackling any mig welding application, look at the charts and tips below. These are based on the material type and thickness, and. Web what material are you welding? Web the welding chart that comes with your machine undoubtedly provides the best guidelines for the welding start. Covering classifications, refrence charts and gas choices. Stainless steel and aluminium amps chart. Use these tips to get the best mig welds. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Nearly every mig welder has a chart — including my millermatic® 211 — often just. One other thing to note here is that these settings are also affected by your welding technique, such as the pattern and speed you move your hand. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web here is a chart that summarizes the mig welding amps according to the three most. Web mig welder settings: Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Web using the correct mig welding settings can make or break the quality of your finished product. One other thing to note here is that these settings are also affected by your welding technique, such as the pattern and speed you move your hand. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. Web in this article, we are going to take a look at how to set up a mig welder along with various other information like how to set up wire welder with gas, metal inert gas welding procedure, what is gmaw welding used for, etc. Nearly every mig welder has a chart — including my millermatic® 211 — often just inside the hinged access cover, which gives you the suggested settings. Covering classifications, refrence charts and gas choices. Before tackling any mig welding application, look at the charts and tips below. Also, consider the amperage settings and the task at hand. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. How to adjust the gas flow rate? There are many mig setting charts available from manufacturers that all vary. Web what material are you welding? It’s a simple process to learn, which is why so many hobby welders use it as their preferred method of welding.aluminum mig welding settings chart

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes

Best Welder for Beginners? 19 Smart Reasons for MIG • WelditU

Mig Welding Settings Chart Metric Pdf

MIG Welding Charts ILMO Products Company

LifeChanging Tools MIG Welder Hot Rod Network

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG Welding Basics Parts of a MIG Welder Video Tutorial Automotive

Mig Welding Settings Chart

MIG Welder Settings Explained (with Chart) Weld Guru

Web The Welding Chart That Comes With Your Machine Undoubtedly Provides The Best Guidelines For The Welding Start.

Web Metal Inert Gas (Mig) Welding Is An Arc Welding Process In Which A Solid Wire (The Filler Metal) Is Continuously Fed Through The Welding Machine And Into The Weld Pool That’s Created By The Arc To Form A Weld.

Stainless Steel And Aluminium Amps Chart.

Web Here Is A Chart That Summarizes The Mig Welding Amps According To The Three Most Common Types Of Metal And Their Thickness:

Related Post: