Machine Finish Chart

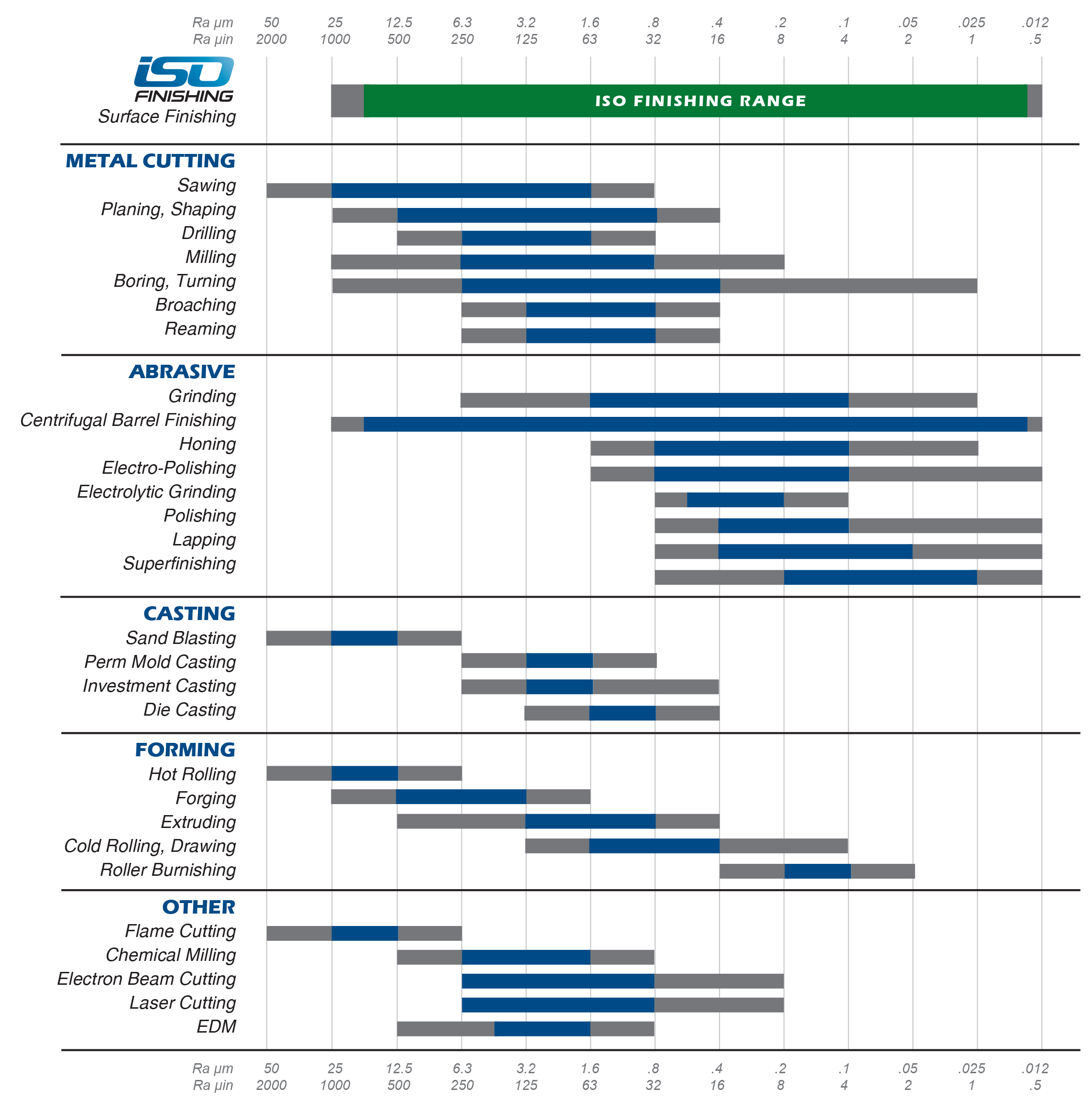

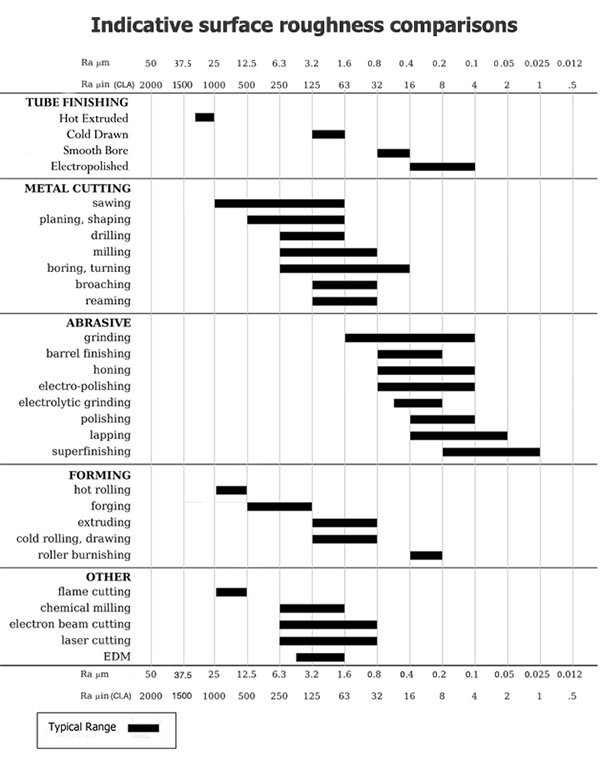

Machine Finish Chart - Manufacturers always use it as a. Web surface finish, sometimes referred to as surface texture or surface topology by machinists, is the quantification and characterization of the texture of the surface. See photos of surface finish comparator for milling,. Web surface finishes chart for cnc machining: Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. After the finishing process is complete, it's vital to conduct thorough testing and quality control checks to ensure that the machined parts meet the. Web learn how to compare and convert surface finish degrees in china and usa, using ra, rz, rms and finish methods. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. Get a specific texture or appearance to have outstanding looks for. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Web testing and quality control. After the finishing process is complete, it's vital to conduct thorough testing and quality control checks to ensure that the machined parts meet the. In this post, we will delve into everything you need to know about surface finish charts, their importance,. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Web surface finish, sometimes referred to as surface texture or surface topology by machinists, is the quantification and characterization of the texture of the surface. Web 14 rows surface finish specification and comparison. Web the surface finishing has 6 impacts for a machined parts: Understand roughness values, ra, rz, and more to enhance your project's quality. Get a specific texture or appearance to have outstanding looks for. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web surface finish is a measure of the overall. After the finishing process is complete, it's vital to conduct thorough testing and quality control checks to ensure that the machined parts meet the. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing. Web the machining surface finish chart provides important instructions for gauging. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. See photos of surface finish comparator for milling,. Web welcome to our comprehensive guide on machine surface finish charts. Web a finish chart can help you compare the differences between units. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Web 14 rows surface finish specification and comparison. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. After the finishing process is complete, it's vital to conduct thorough testing and quality control checks to ensure that. Web a finish chart can help you compare the differences between units so that you can convert them when necessary. See photos of surface finish comparator for milling,. Web the surface finishing has 6 impacts for a machined parts: Understand roughness values, ra, rz, and more to enhance your project's quality. Web learn how to compare and convert surface finish. Web surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. When discussing cnc machining, one of the most important variables is what finish will be applied to the. Manufacturers always use it as a. Web surface finish chart by machining technology in the chart. Web surface finishes chart for cnc machining: Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. Web testing and quality control. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Improve corrosion and chemical resistance effectively. Web the following charts and tables convert surface finish or roughness between selected industry standard units. It depends on the structure of the metal before and. Web 14 rows surface finish specification and comparison. Improve corrosion and chemical resistance effectively. Understand roughness values, ra, rz, and more to enhance your project's quality. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web the finish on a metal surface after machining depends mainly on the material and some are as follows. Web the surface finishing has 6 impacts for a machined parts: Web surface. Web surface finish, sometimes referred to as surface texture or surface topology by machinists, is the quantification and characterization of the texture of the surface. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. Web the surface finishing has 6. Web learn how to compare and convert surface finish degrees in china and usa, using ra, rz, rms and finish methods. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. Manufacturers always use it as a. Web additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. It depends on the structure of the metal before and. Improve corrosion and chemical resistance effectively. See photos of surface finish comparator for milling,. Web surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. In this post, we will delve into everything you need to know about surface finish charts, their importance,. Understand roughness values, ra, rz, and more to enhance your project's quality. Web testing and quality control. Web the surface finishing has 6 impacts for a machined parts: Web surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Web surface finish, sometimes referred to as surface texture or surface topology by machinists, is the quantification and characterization of the texture of the surface. Web welcome to our comprehensive guide on machine surface finish charts.Machining Surface Finish Symbols Chart

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

Machining Surface Finish Chart, Conversion, Comparator, Method, Degree

Machining surface finish chart, conversion, comparator, method, degree

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

Surface Roughness Chart Understanding Surface Finishes RapidDirect

Surface Roughness Chart Comparison ISO Finishing

Surface Finish Guide 5.5" x 8.5" Tool Box CNC Shop eBay in

Surface Finish Destiny Tool

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

After The Finishing Process Is Complete, It's Vital To Conduct Thorough Testing And Quality Control Checks To Ensure That The Machined Parts Meet The.

When Discussing Cnc Machining, One Of The Most Important Variables Is What Finish Will Be Applied To The.

Web The Machining Surface Finish Chart Provides Important Instructions For Gauging Standard Surface Finish Characteristics.

Web Typically These Charts Provide Guidelines Regarding The Measurement Of Standard Surface Finishes, Such As:

Related Post: